Stresstech XStress Robot

Xstress Robot general

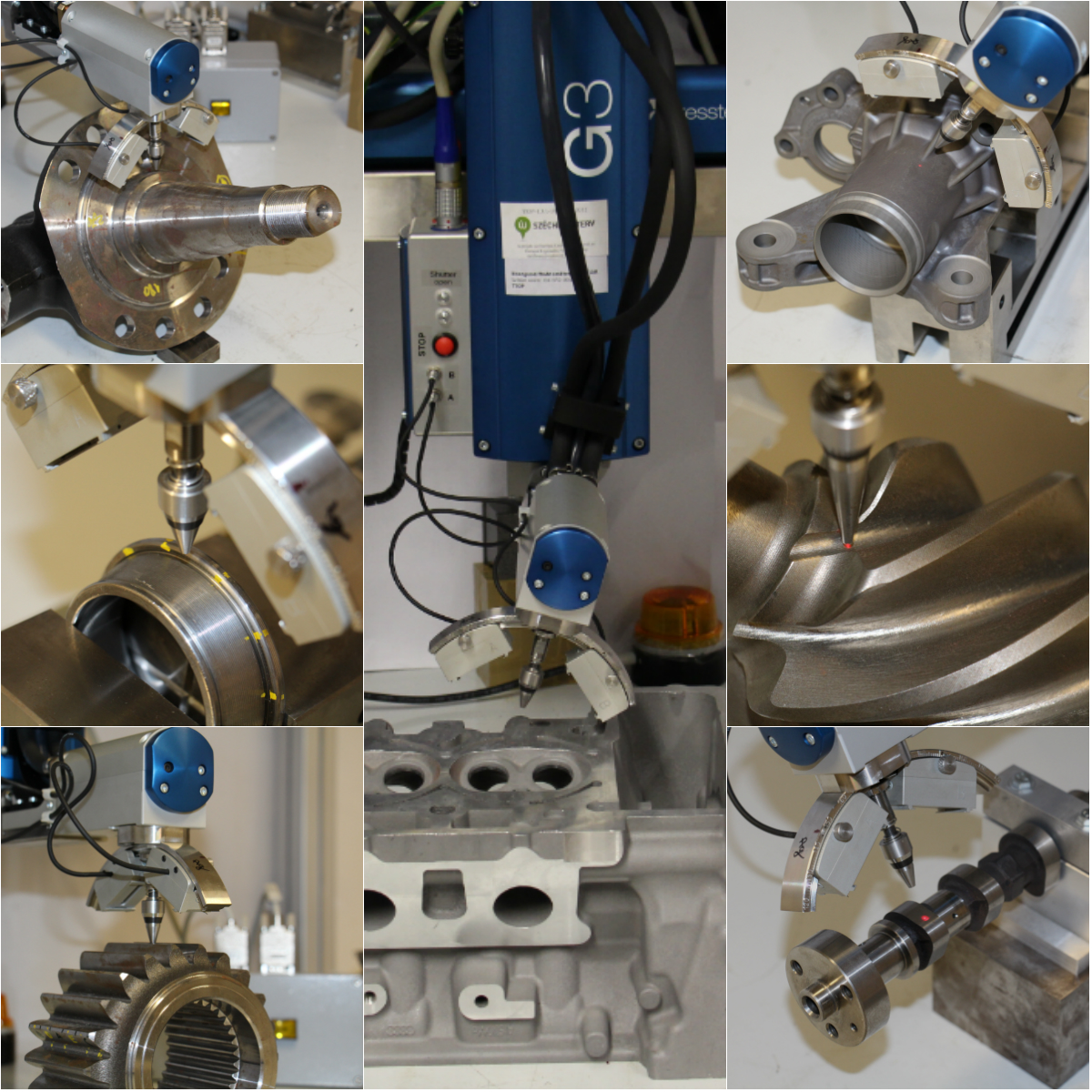

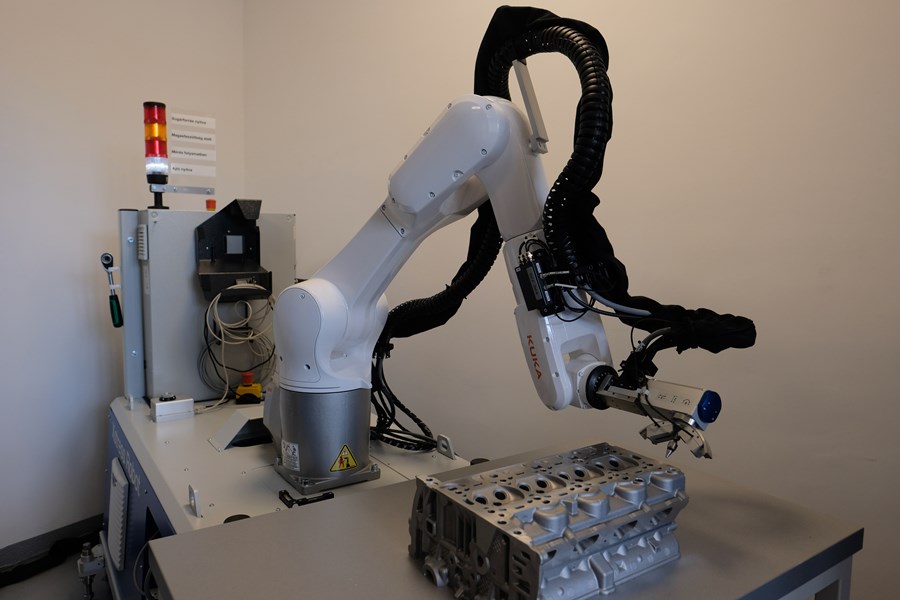

XStress Robot is an advanced X-ray stress analyser. The robot goniometer includes the tube holder unit, attached to the robot arm which can be moved quickly to the different measurement areas on the surfaces. The robot handles all goniometer functions such as tilting and rotation. Stress and retained austenite measurements not only on flat surface of complicated components large or small can be handled. Accurate depth profile measurements are also available by electroetching system. Nondestructive pole figure determination by our method.

- Accurate 6-axis industrial Kuka robot.

- Automatic mapping on complicated parts.

- Movable or fixed installation with safety enclosure.

- Two NMOS position sensitive detectors.

- XTronic software for running the measurement and calculating residual stresses and retained austenite content.

- A high precision camera capable of directly measuring the X-rays exiting from the X-ray diffractometer. It allows XTronic software to align system movements along Euler’s sphere to guarantee the most precise movements possible.

Features:

- Two symmetrically positioned MOS position sensitive detectors

- 2θ-range of the detectors: continuously adjustable within 110° to 165°

- Standard measurement distance 50 mm

- Replaceable collimators

- 1, 2, 3, 4 and 5 millimeter spot sizes, split collimator also available

- Cr, Cu, Mn X Ray tubes Max output 30 kV/9 mA/270 W

- Xstress main unit (high voltage generator)

- X-ray power supply 5–30 kV/0–10 mA freely adjustable within limits

- self-contained liquid cooling system, includes all interlocks required for complete safety, universal power input.

- Dept profile measurement unit

- Elastic constant determination system allows for the experimental determination of a materials X-ray elastic constant in adherence to ASTM E1426 or EN15305 using a strain gauge or load cell that is automatically controlled by the XTronic software.

- XTronic software

- XTronic takes care of the measurements with the Xstress systems from running the measurement to calculating the residual stress or retained austenite values. XTronic software fulfills the new European X-ray residual stress testing standard EN 15305.

- fully featured Windows software

- hardware operation control: detectors, DC motors, power supply, shutter, safety interlock functions, voltage and current, etc.

- automated calibration with zero stress powder samples to set goniometer to sample distance

- project manager for depth distribution measurement and all kinds of mapping measurements

- library functions for material parameters

- modified sin2Χ and Ω-mode

- peak shift determination with the most known methods such as Cross-correlation and Peak fit methods.

- peak fit with eight different functions and three background options: Gauss, Lorentz, Modified Lorentz, Intermediate Lorentz, Pearson VII, Split Pearson VII, Pseudo-Voigt, Split Pseudo- Voigt

Additional infrastructure: Stresstech G3R

Stresstech G3R Centerless X-ray diffractometer for laboratory and onsite measurements. Compatible with the XStress Robot system accessories. Possibility of residual stress, retained austenite and pole figure determination.