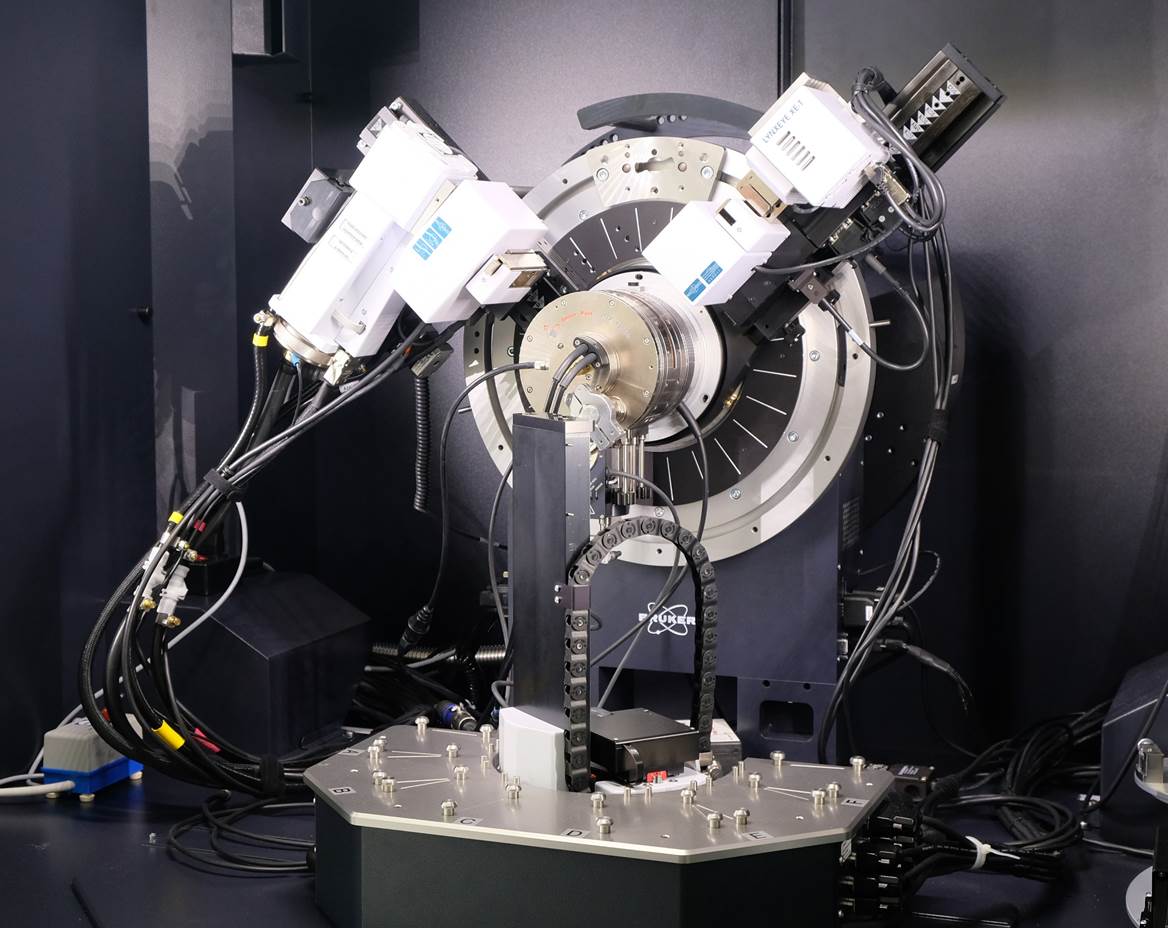

Bruker D8 Discover XRD SAXS XRR

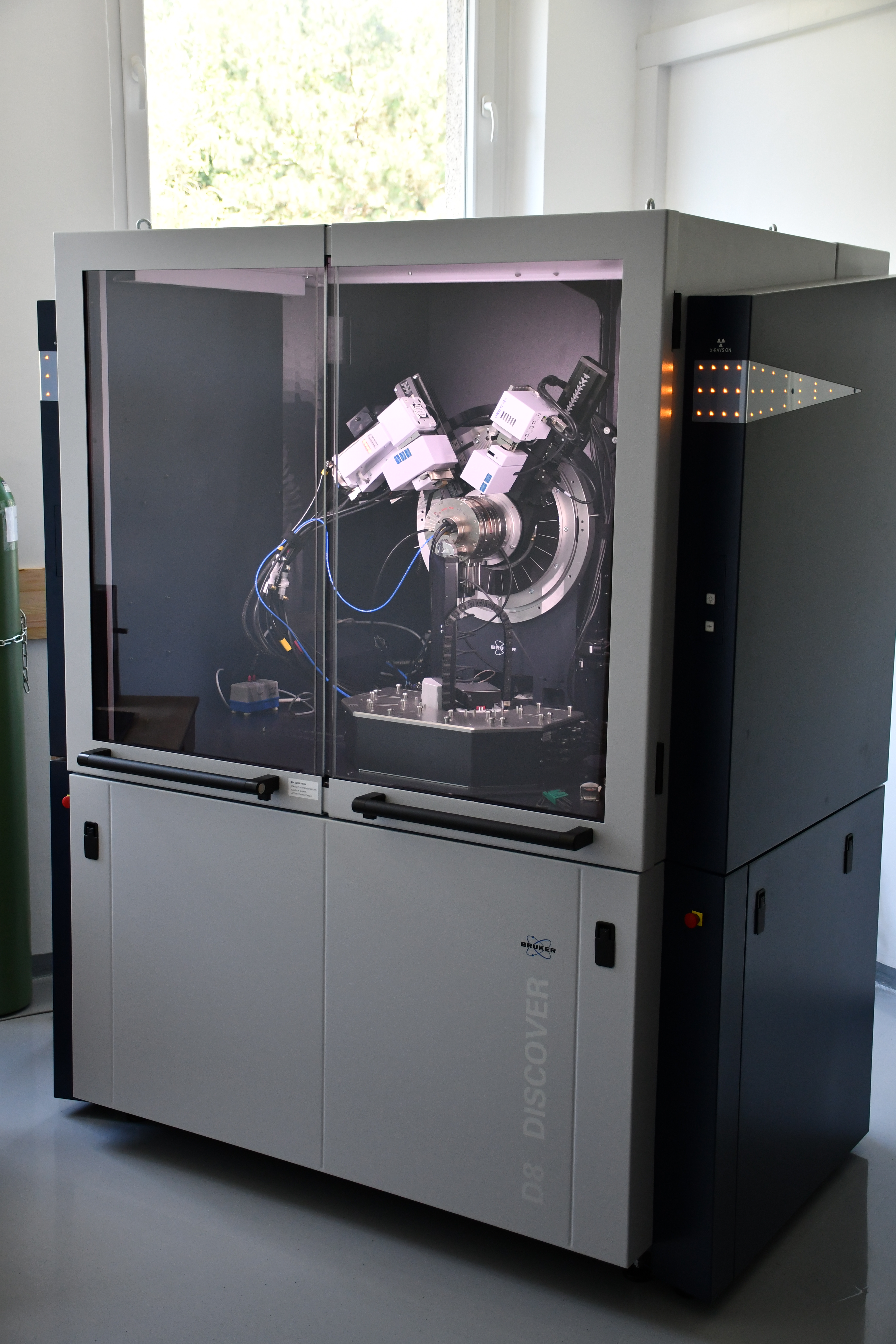

The ultimate multipurpose Xray diffractometer provides diffraction, reflectometry, or small angle scattering for structural characterization of powder, bulk, polycrystalline materials or multilayered thin film at ambient or elevated temperature.

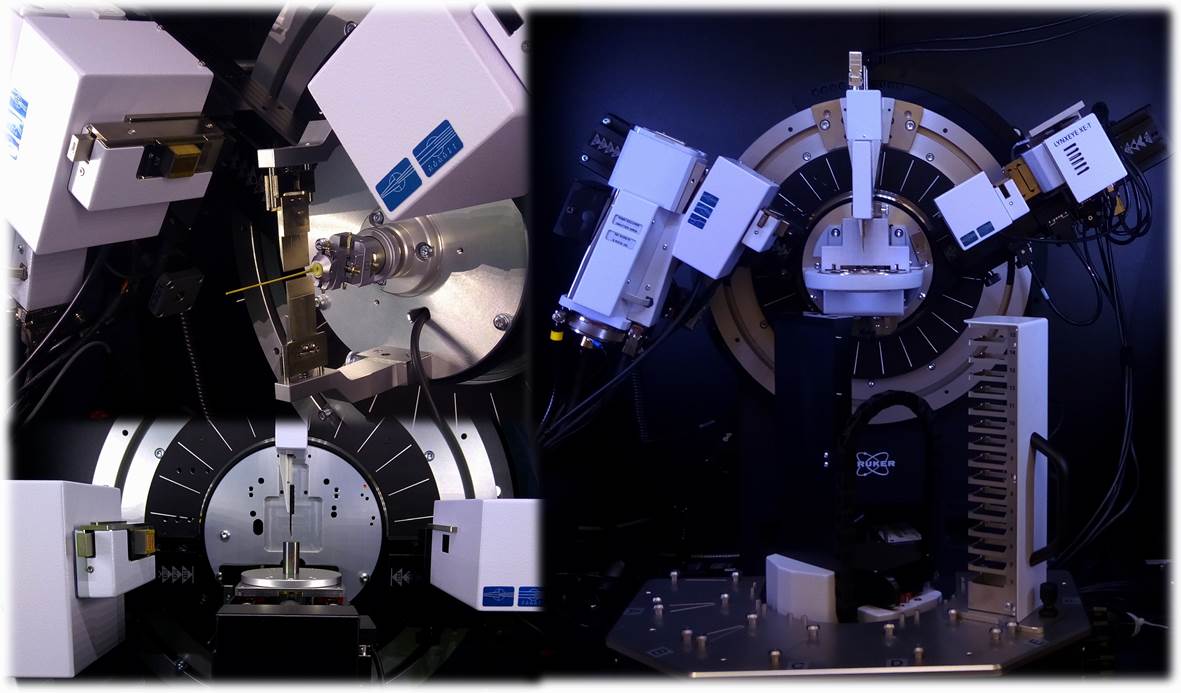

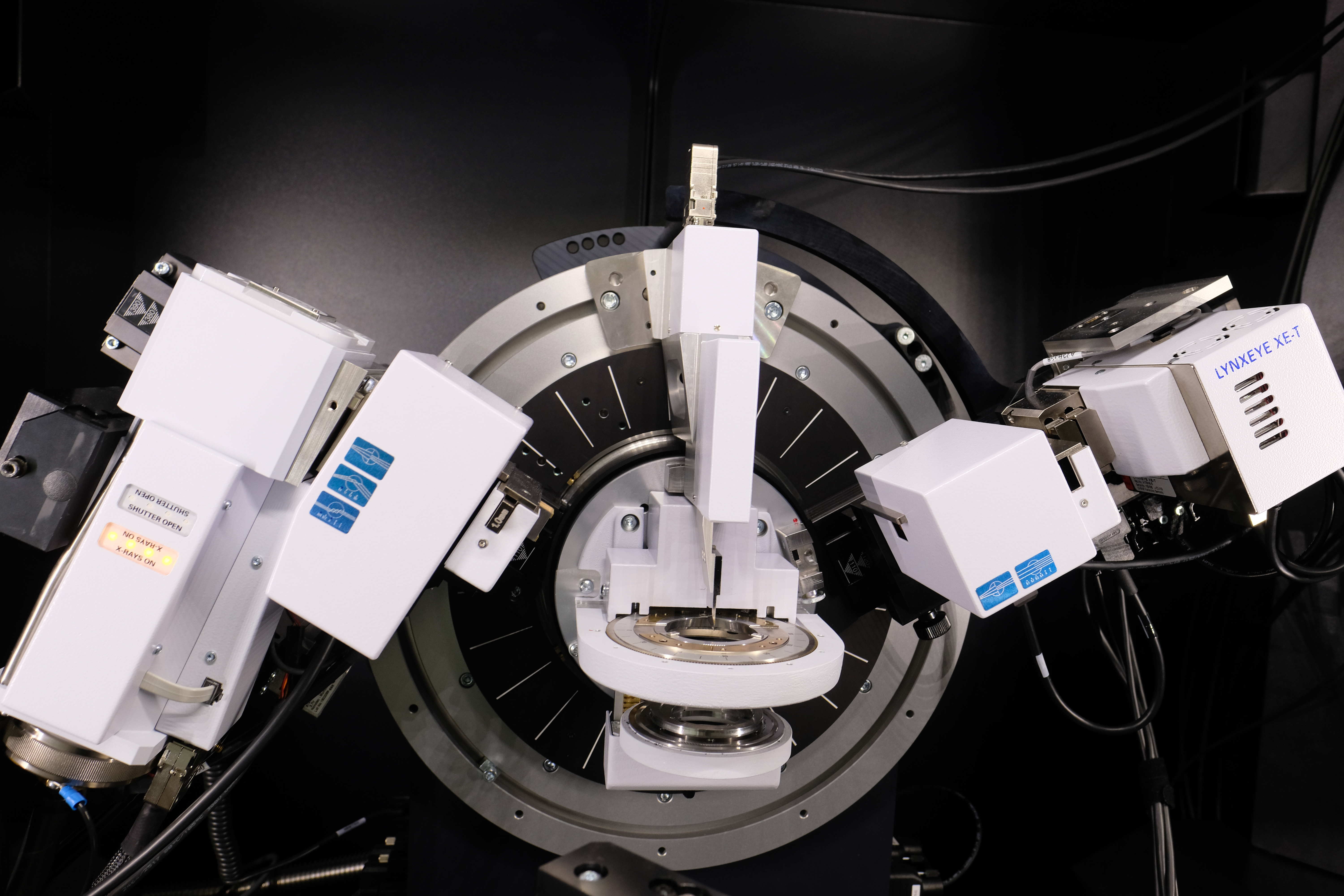

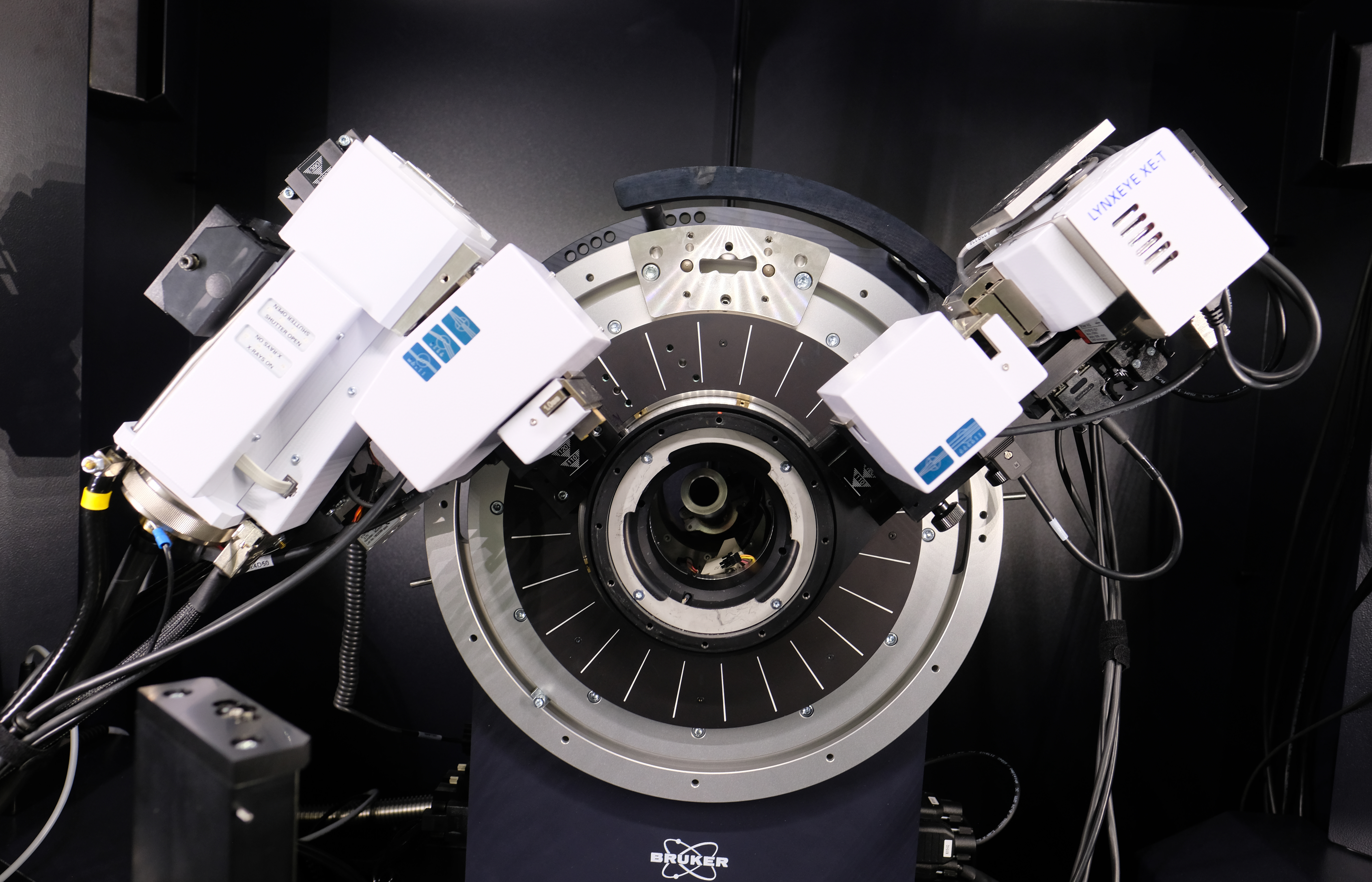

Bruker D8 Discover instrument, with DaVinci control, automatic attachments recognition push-plug and vertical θ-θ goniometer, push-plug 2.5°-os axial Soller slits. The DaVinci control recognizes each active (attached) optical part with microsensors and allows software controlled modification of settings. With the push-plug system the attachments are readily changed, the correct switching is immediately transmitted by the DaVinci control. This functionality is exploited to maximum at planning of measurement, which are started only if the correct attachments are set to the correct mode. The tube is long-fine focus type with Cu-anode, allowed operation with max. 50 kV voltage and 50 mA current. The instrument is also capable of small angle X-ray scattering (SAXS) and X-ray reflectometry (XRR) measurements. The low and small angle measurements are run with software controlled, precision motor alligned air-scatter slit, with fixed or automatically varied opening degree (motorized air scatter slit, MASS), thus measurements can be recorded from 0.01°(2θ) starting angle.

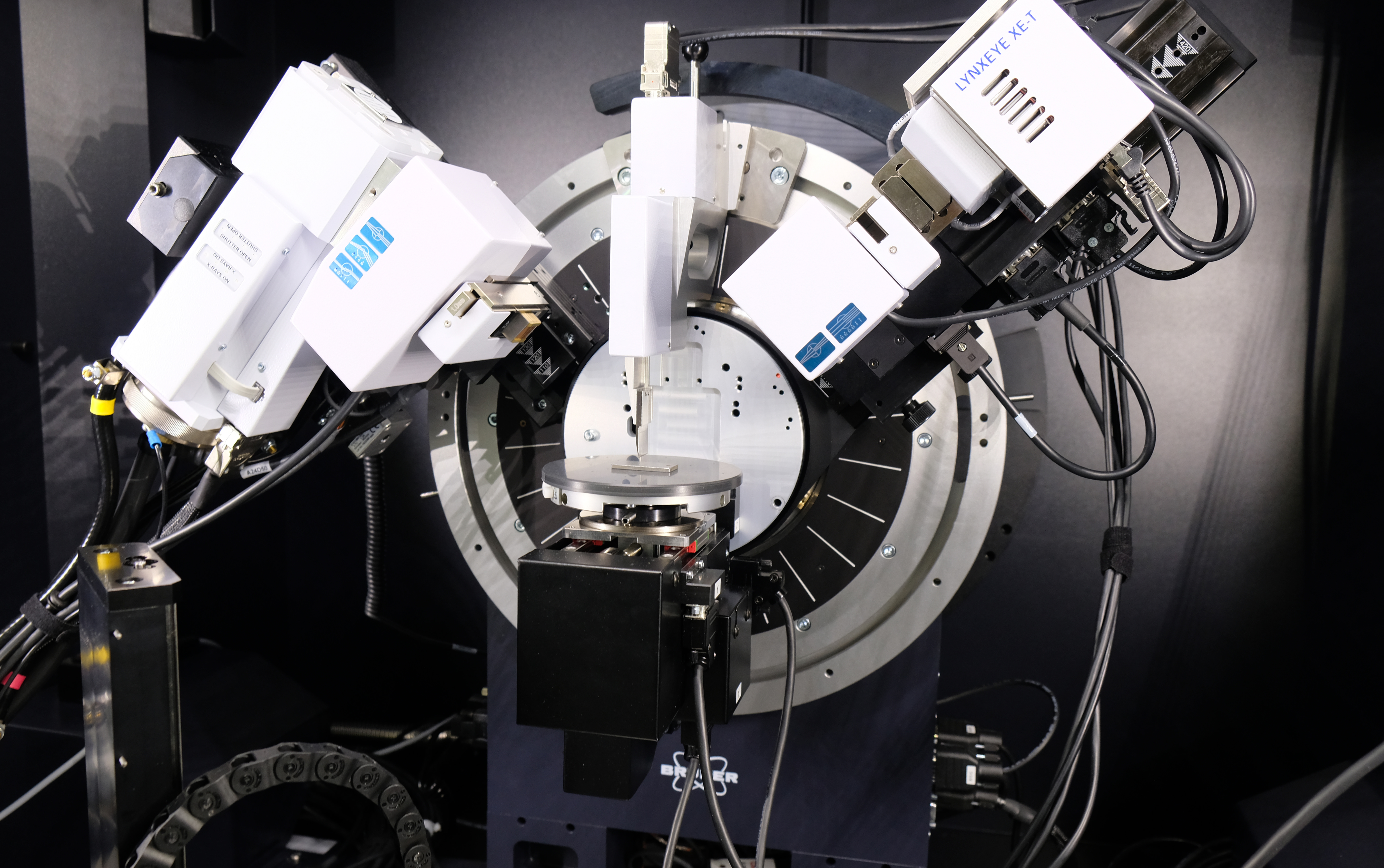

The TRIOTM optics is directly attached to the X-ray tube (to the left), allowing software controlled switching between dynamic slit system, Bragg-Brentano, Göbel mirror and Ge Kα1 monochromator. The sample stage (in the middle) works with circular rotated sample holders, with the MASS above. The LynxEYE XE-T semiconductor position sensitive detector has 3° linear opening (to the right) and is equipped with TWINTM optics for software controlled switching between dynamic slit system and 0.2° equatorial Soller.

The TRIOTM optics on the primary (tube) side allows switching between three geometries, by software controlled precision motor.

- Regular Bragg-Brentano (parafocusing) geometry has dynamic slit system with the options of constant illuminated area, fixed slit sized or divergence in degrees.

- Parallel beam geometry with Göbel mirror, equatorial divergence < 0.5°, for powder specimens, uneven surfaces, microgram samples and non-destructive measurements.

- Ge-monochromator for pure Cu-Kα1 parallel beam, for high resolution (HRXRD) and small angle scattering SAXS measurements.

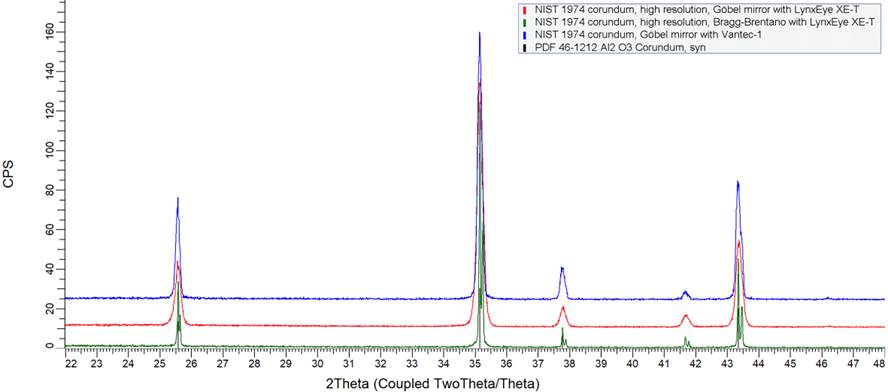

TRIOTM Bragg-Brentano (FWHM=0.045 °2θ), Göbel mirror (FWHM=0.180 °2θ) and Cu-Kα1 monochromator (FWHM=0,056 °2θ)

For smooth and plane, not nanocrystalline samples the Bragg-Brentano geometry allows the measurement of needle sharp peaks.

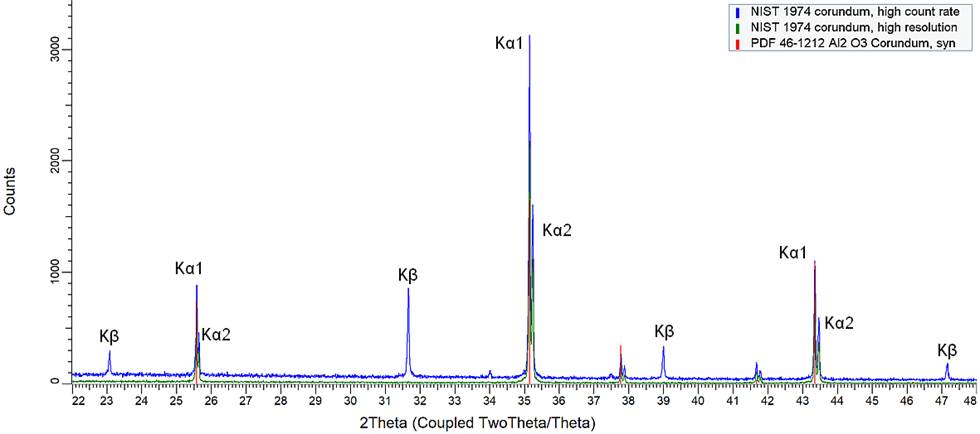

The secondary (detector) side optics is a multifunctional system on its own, the LynxEYE XE-T semiconductor position sensitive detector with 3° opening has 75x75 μm sized individual sensors and < 380 eV resolution. The resolution of energy discriminator is adjustable, the optimal settings are the intensity optimization (high count rate) and energy resolution optimization (high resolution), applicable geometries:

- 0D: corresponds to scintillation counter, preserving energy resolution, size of active window is adjustable; works with any stage and any geometry

- 1D: position sensitive detector, the high resolution in Bragg-Brentano geometry solves monochromatization beyond noise and fluorescence filtering, size of active window is adjustable

- 2D: area detector, manually tilted with 90°, preserves energy resolution, size of active window is adjustable; works with any stage and any geometry

Energy discrimination of the detector is adjustable, the two optimal settings are high count rate and high resolution.

The airs scatter slit is centered with precision to the sample surface, reducing to minimum the background elevation at low angles, noise of the measurements can be reduced. In Bragg-Brentano geometry with the constantly illuminated sample are setting of the dynamic slit system can be automatically adjusted to the opening of MASS and detector active area. This is the dynamic beam optimization (DBO) which allows diffraction measurements from 0.01° (2θ).

The goniometer can be used even without sample stage. The hollow goniometer center allows the handling of cables, gas or vacuum tubes. Also this setting allows the measurement of the surface of samples with several tens of centimeters in size, by the aid of sample handling devices.

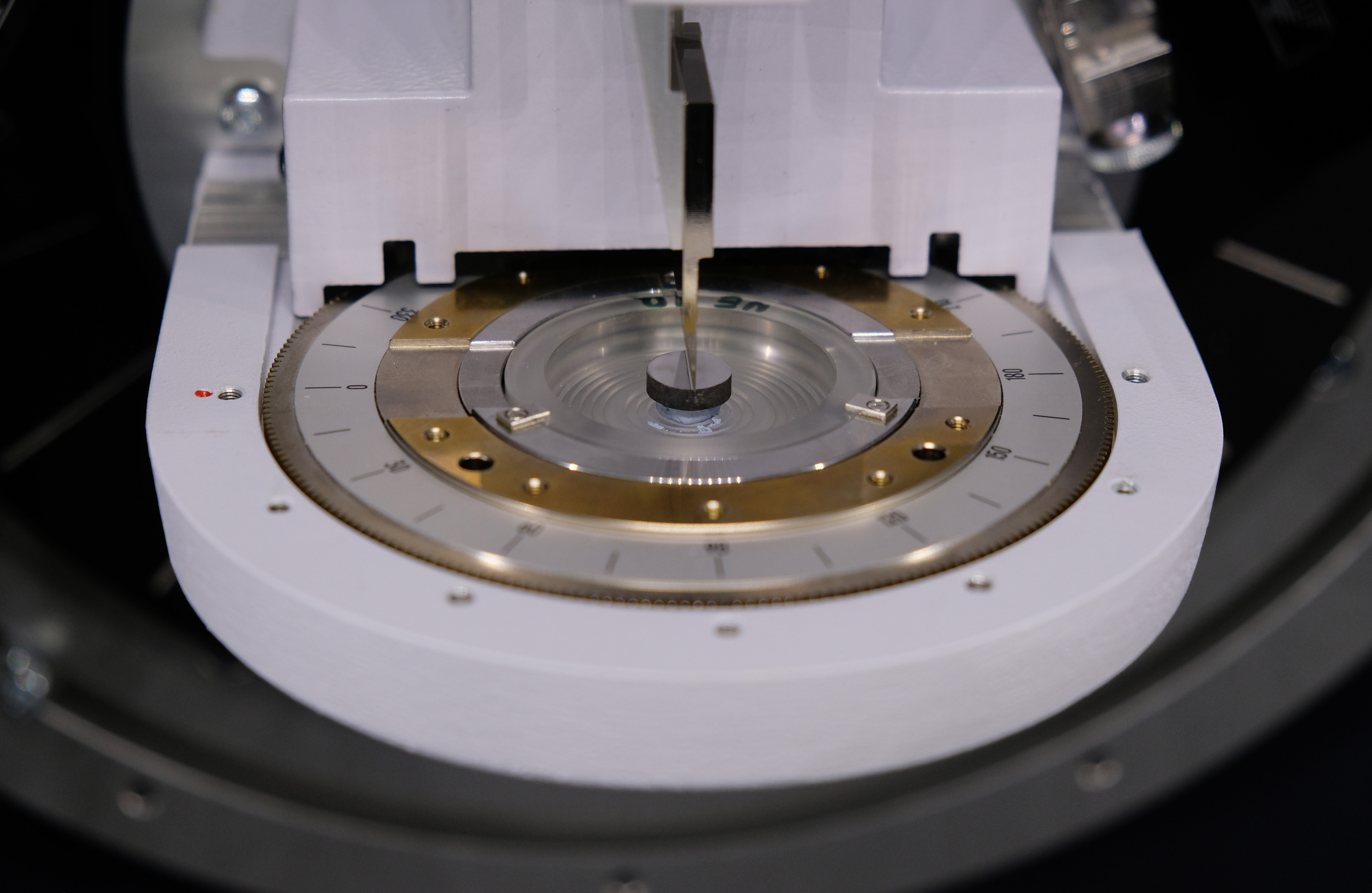

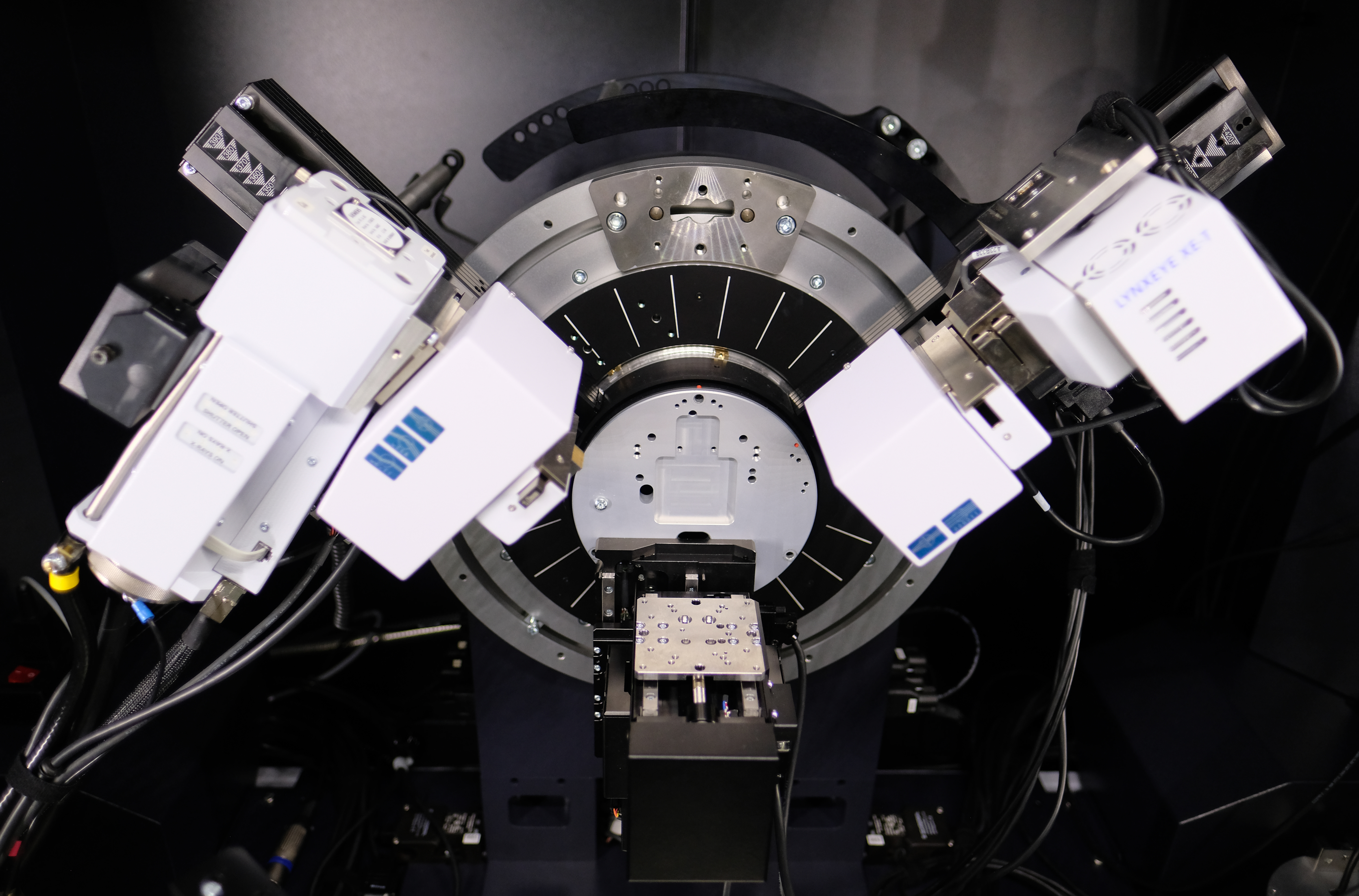

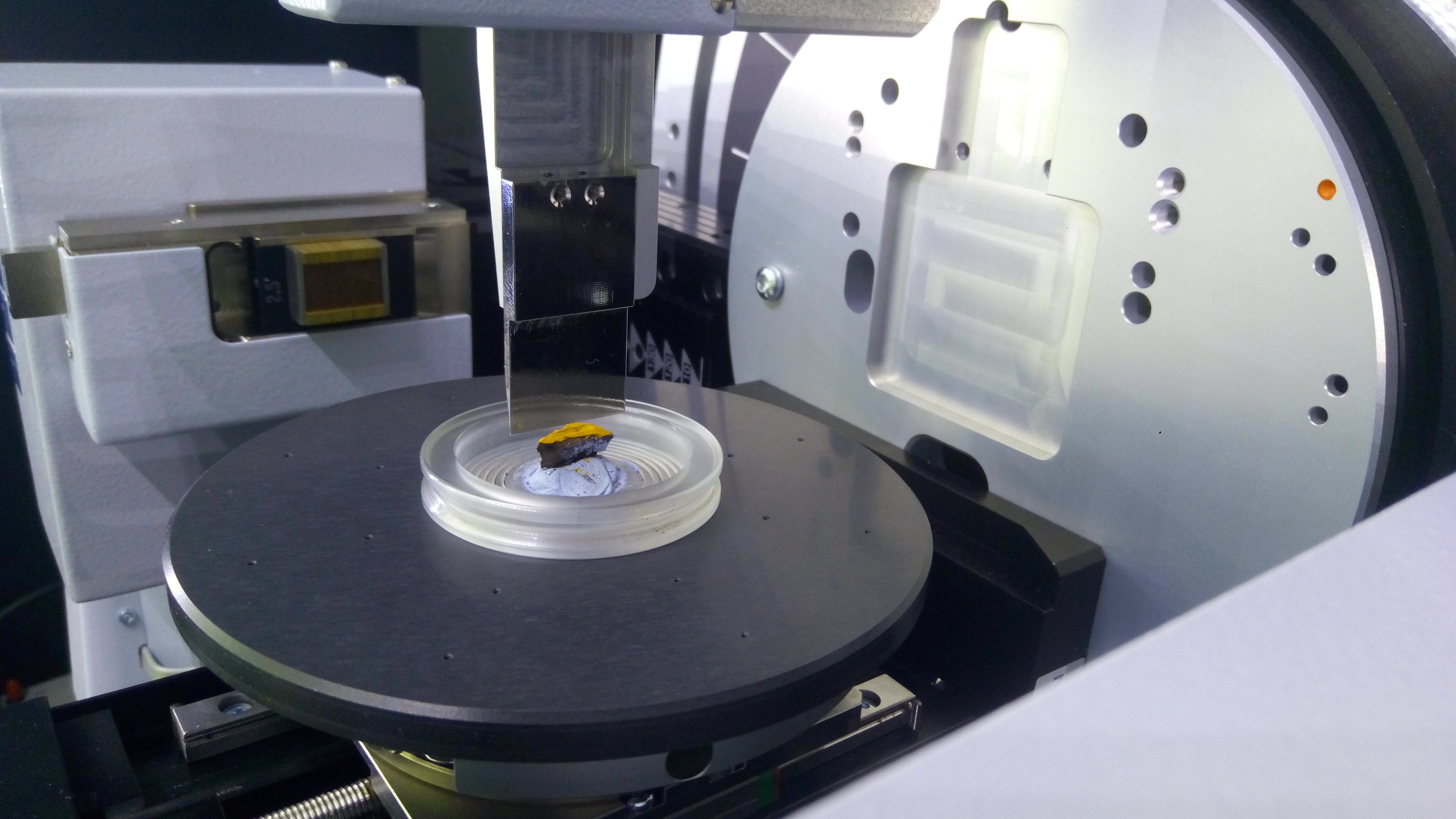

The 3-axis sample stage with mount base, for attaching various sample holders and stages. Can be used for block samples, surface grazing incidence (GI), SAXS and XRR measurements; works with any geometry with a suitable sample.

The 3-axis sample stage with reduced X-ray scattering for slab samples, using MASS. The stage has vacuum system for locking the very thin, fragile and lightweight samples.

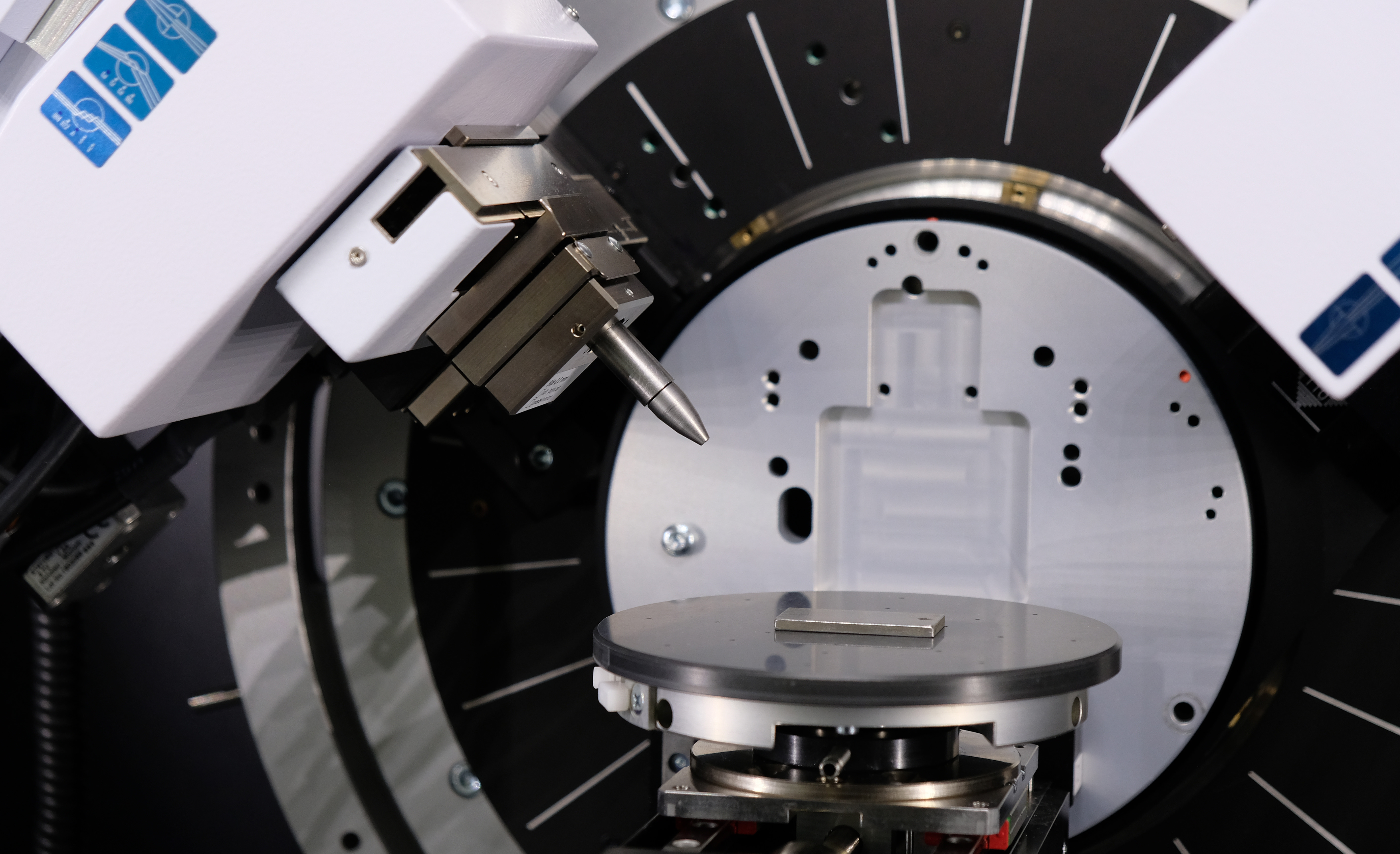

The pinhole collimators allow the area selective phase analysis, mapping depth profiling. The 2, 1 and 0.3 mm sized pinholes are currently available.

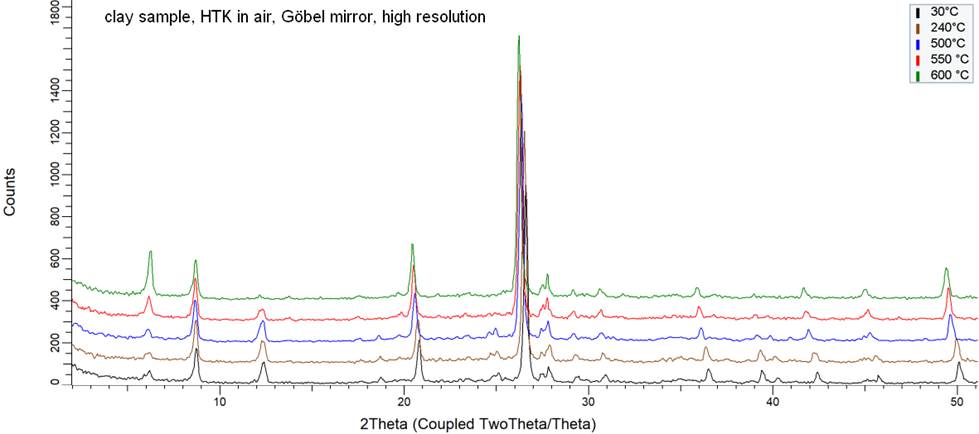

By the use of Göbel mirror, the MASS detector high resolution mode, nanocrystalline-amorphous Fe-oxyhydroxide mineral samples can be investigated.

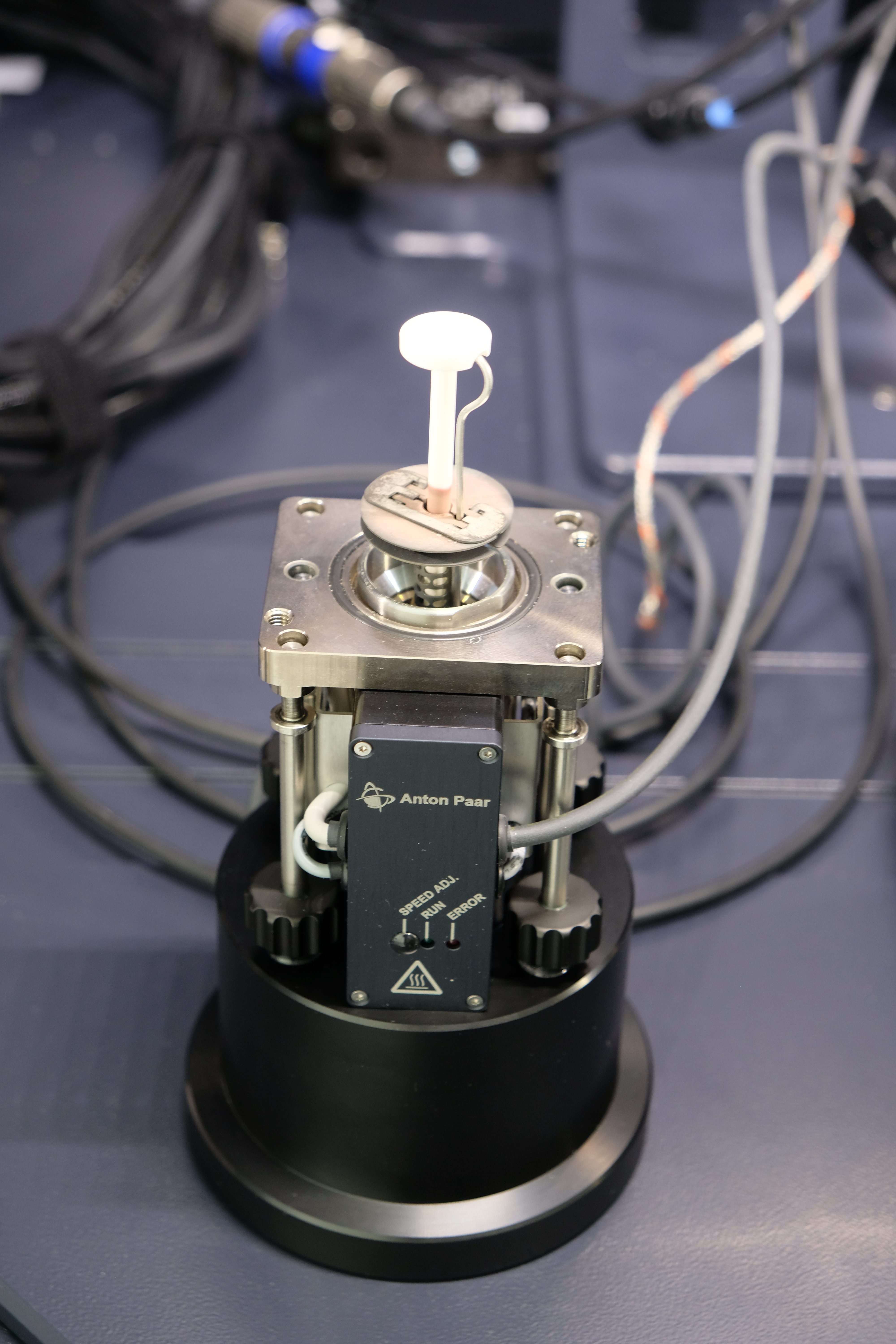

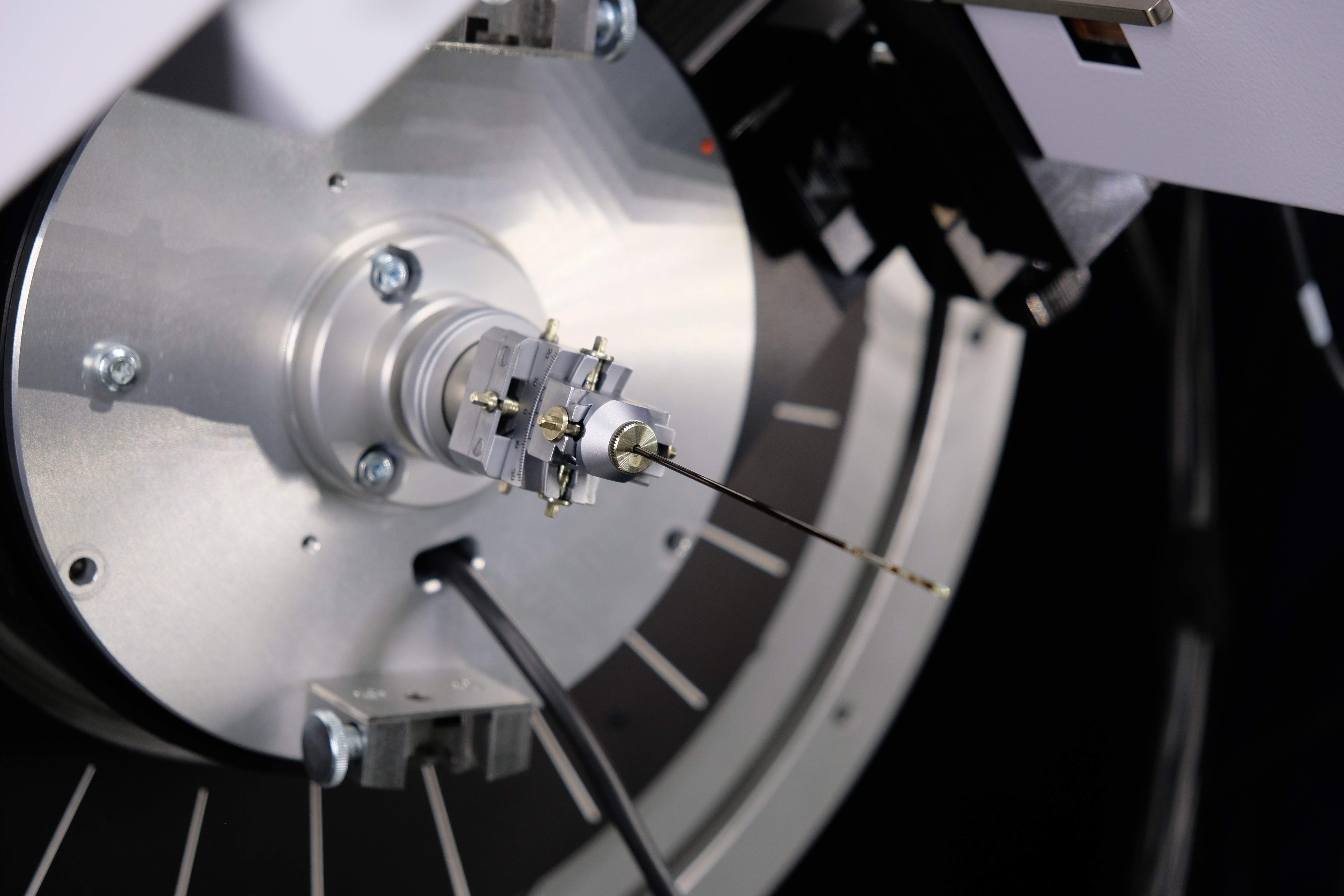

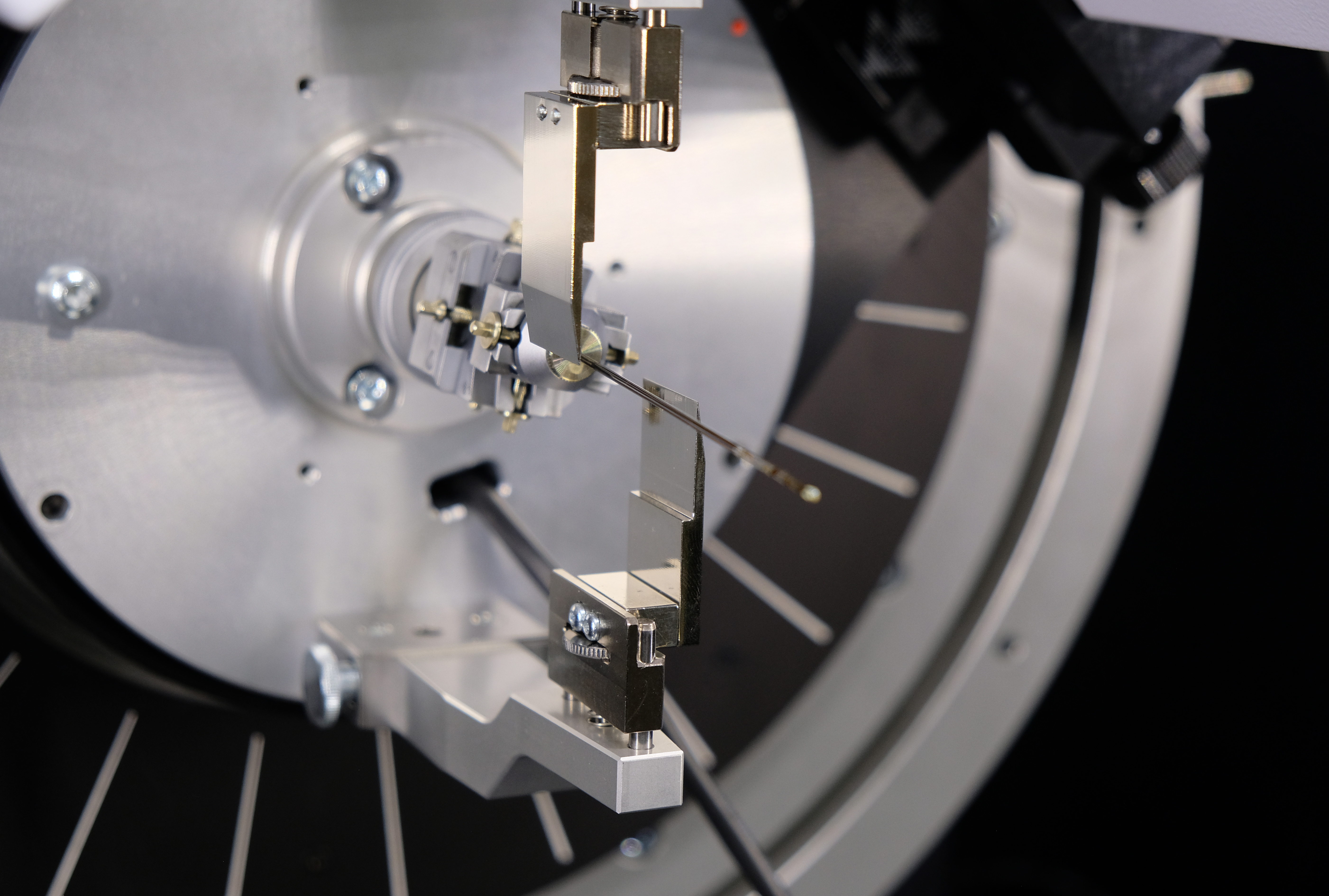

Capillary sample on the stage with rotatable head. Powders, fluids and suspensions can be measured.

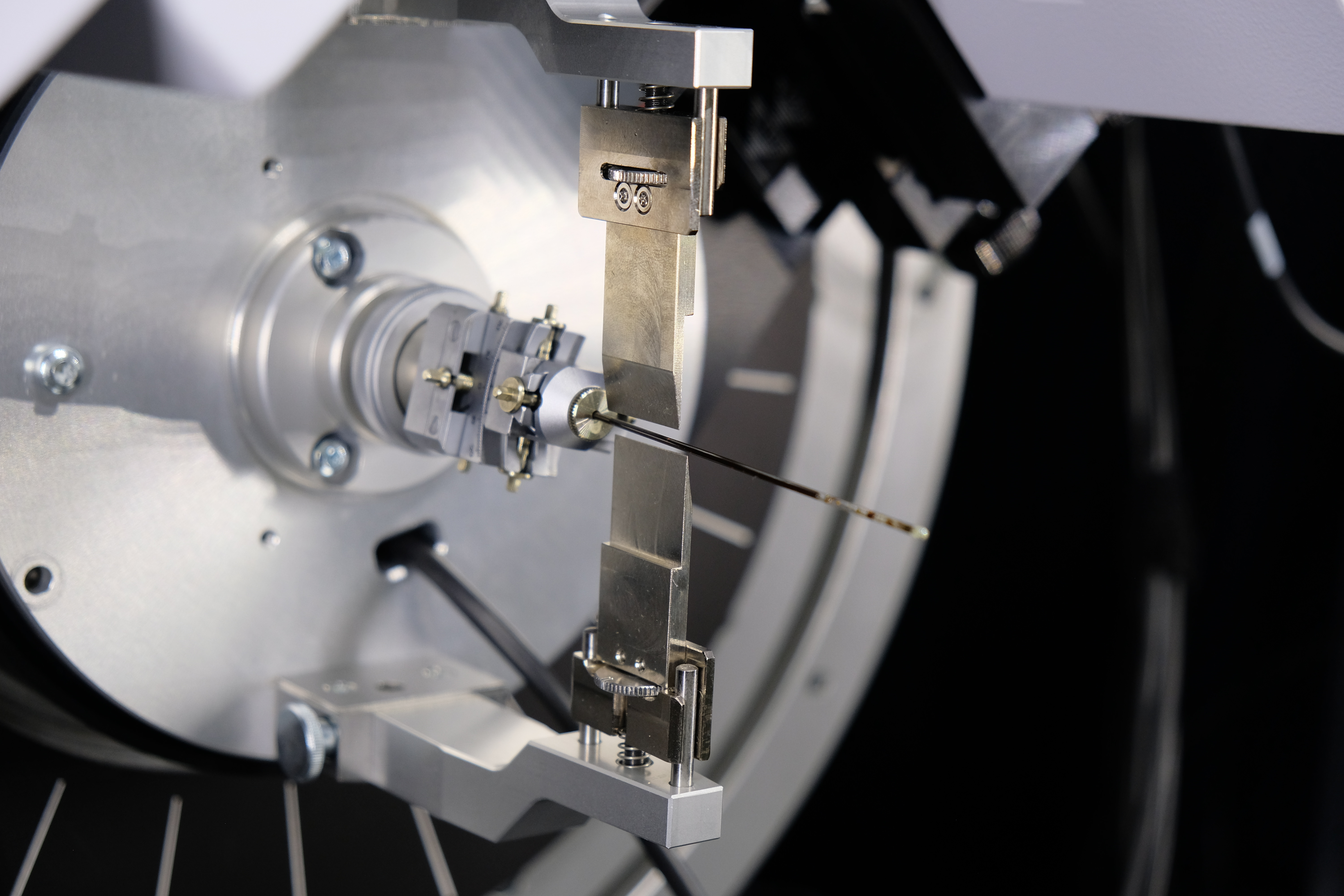

Capillary stage with the air scattering slit system for small angle scattering.

Capillary stage with general air scattering slit system.

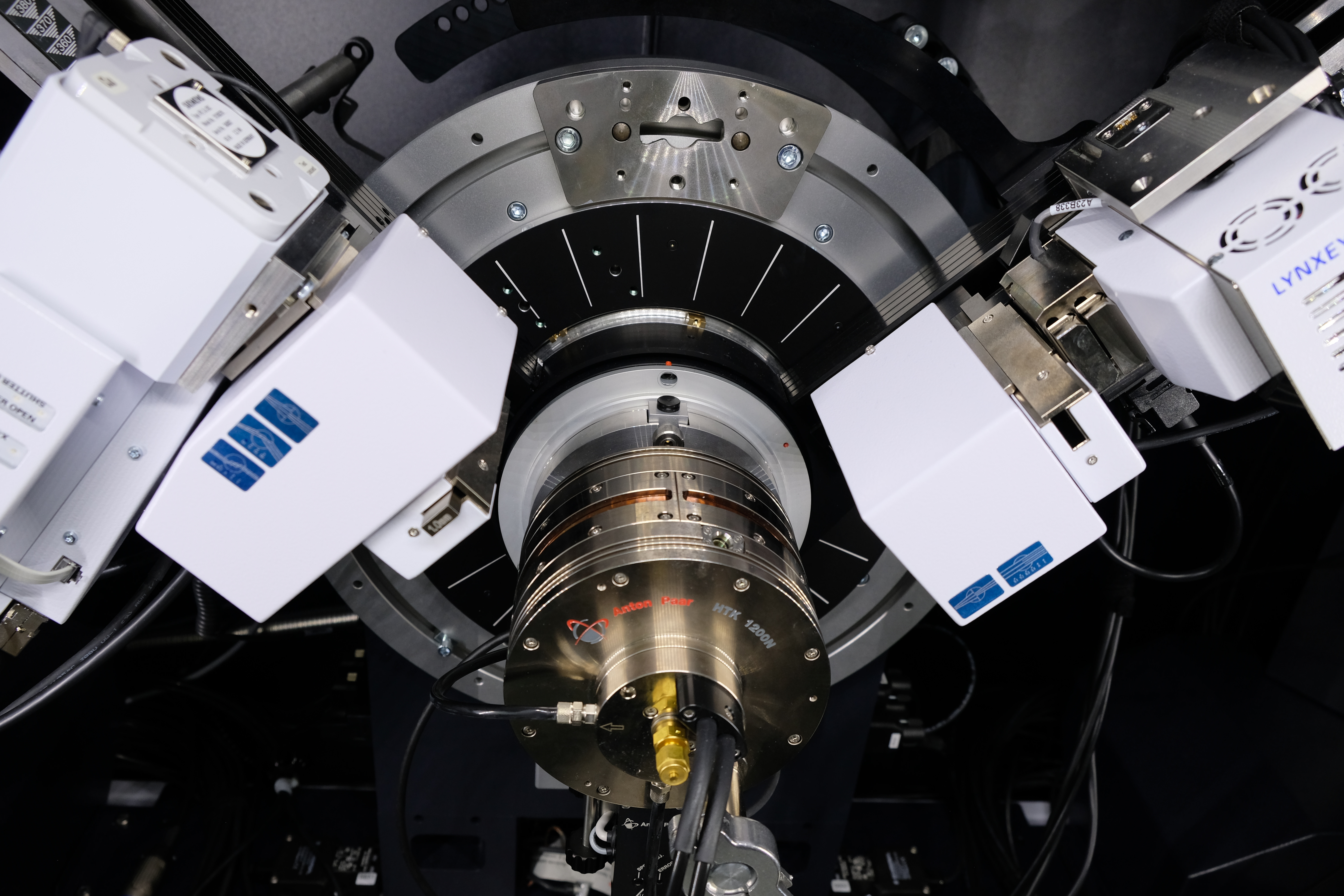

HTK 1200N: heating chamber with corundum inwall, motorized Z-axis for centering block sample surfaces to the sample plane, rotatable sample holder, heating range 25 and 1200 °C with min. 1°C/min, max. 60°C/min heating and cooling rate; soaking, cyclization can be preprogramed unconditionally; measurements can be carried out in vacuum (2/10-3 mbar) or inert gas atmosphere; works with any geometry with a suitable sample. The chamber is attached with push-plug system, in compact mode, does not require the removal of sample changer robot.

The X-ray window of the chamber allows large angle measurements up to 130 °(2θ). The flow-through water cooling allows controlled cooling or temperature hold time.

Motorized precision Z-axis drive for the measurement of slab or block samples.